A perfect solution

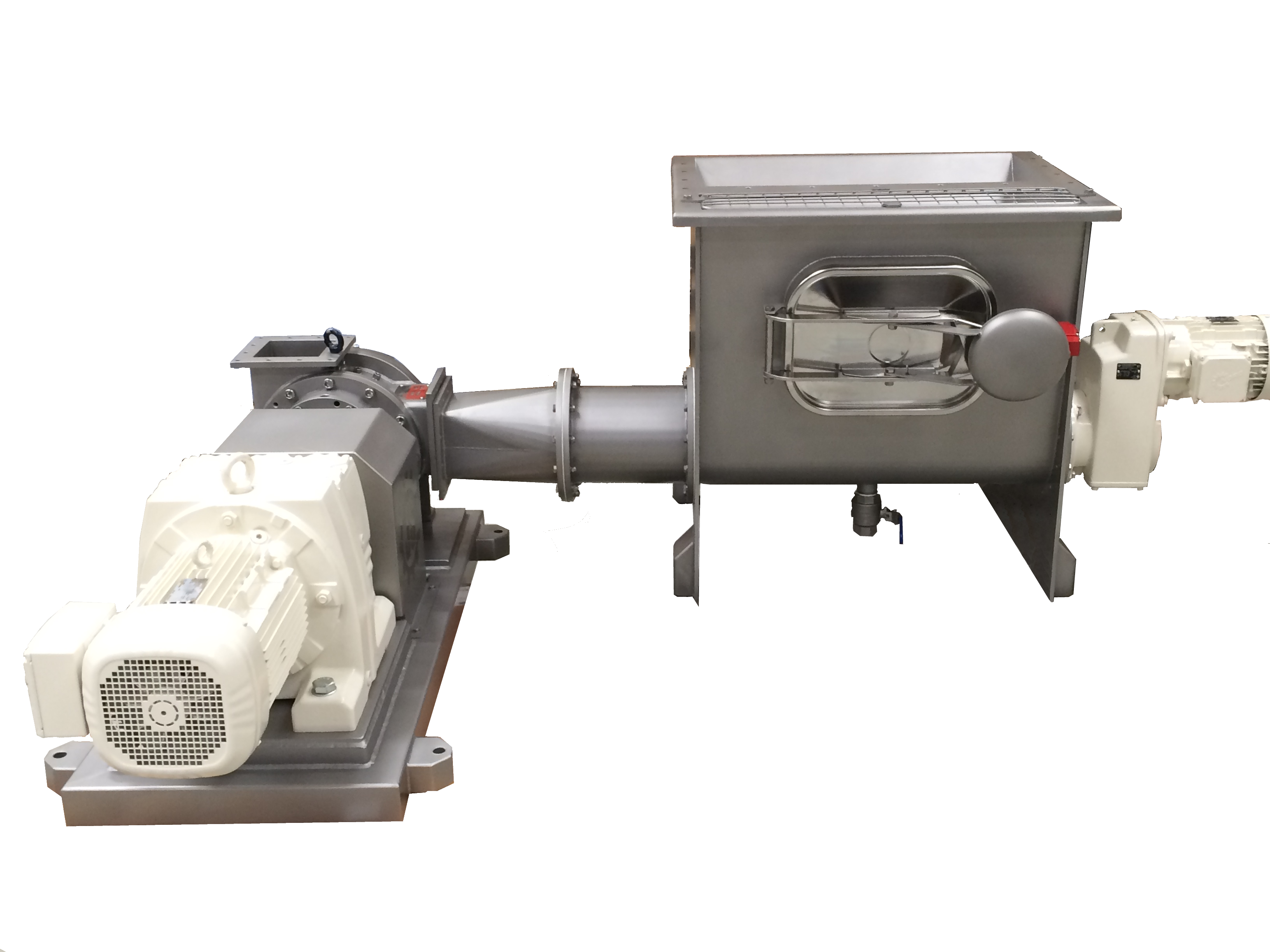

A high filling rate ensures optimum utilization of the pump's capacity. The infeed hopper is designed especially for use with the lamella pump and is designed to handle the same hard products within the same industries.

The infeed hopper can be used for whole industrial fish, fish cuts, animal by-products of poultry, cattle and pigs, and other offal.

The JS Standard infeed hopper consists of a metal container designed to give the product optimal access to the screw. A bend in the wall of the bin, which partially goes over the screw, helps to prevent the product from moving with the screw. The product is effectively pushed forward to the pump.

Fulfilling specific needs

Customized Infeed Hopper solutions

High quality Infeed Hopper

Only quality materials are used without savings in the thickness of the goods and all our employees take pride in delivering a high-quality piece of craftsmanship. This ensures a solid and durable product where the quality cannot be doubted.

JS Standard infeed hoppers are supplied for Lamella pumps in sizes LAP250/70 & 350/90. If you want an infeed hopper for one of our other pump sizes, this is also an option – contact us for further information.

Specially designed infeed hoppers are produced on request and are of course delivered in the same high quality. Our technicians are ready to calculate and design the infeed hopper that fits the customer's needs.

We advise and come up with solutions that will always ensure our customers a satisfactory result.

The driving force of the screw can be supplied either as electric or hydraulic. KW and torque are calculated by product and quantity.

Need help?

CONTACT A JS EMPLOYEE

Please do not hesitate to contact us if you need guidance

or advice on anything relating to our products.

We will do our utmost to meet your needs and demands.